Tooling and Moldmaking for the Production of Rubber Composite Parts

For 35 years, toolmaking has been one of our core competencies. We manufacture custom tools and molds for the production of molded rubber and composite parts.

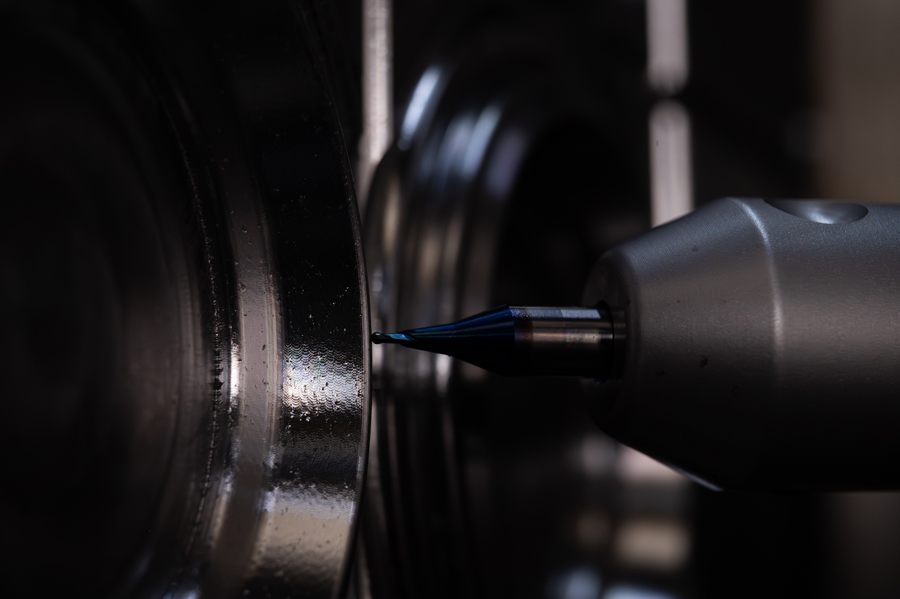

Precision starts with the tool. So does speed.

Short development times

Tools and molds are designed and manufactured in-house, saving time and additional iterations.

High precision

We ensure micrometer-level accuracy for exact compliance with specifications and consistently deliver high component quality.

Flexibility

Adjustments to the tools are possible at any time and are carried out promptly by us.

Seamless transition from prototyping to production

The toolmaking and production departments work hand in hand, guaranteeing tool concepts that are production-ready.

Cost efficiency

We develop various tooling and production concepts during the quotation phase and select the most economical option for you.

Prototyping and Production Tooling

Design & Development

Manufacturing & Initial Sampling

Adjustments & Optimization

Maintenance & Repair

We ensure the reliability of tools during ongoing production processes. Maintenance and continuous optimization extend service life and ensure stable processes.

Our Tooling Services

Smart Manufacturing: We manage the entire toolmaking process in-house.

- Toolmaking is our core competency

- 100% in house expertise

- Fast response times for tooling modifications

Insights into Our Customer Projects

Rubber Metal Quick Clamping Device

Learn more

Rubber Plastic Membranes

Learn more

Vulcanized Sheet Metal Profiles for MRIs

Learn more

Do you have questions?

We have answers!

Which materials can be used in toolmaking?

How quickly can prototype and production tools be designed and produced?

Can existing tools be adapted or optimized?

What quantities can be achieved with the tools?

What is the service life of a tool?

Which cost factors influence toolmaking?

Accelerated production: We combine in-house toolmaking with over 35 years of manufacturing experience

- Express service: Receive your first prototypes in 2 weeks, and start series production within 4 weeks

- 100% on time and delivered with zero defects

- Get a response within 24 hours