Rubber and Metal Technology

We manufacture molded rubber and rubber-metal composite parts to deliver an exceptional customer experience. High quality, reliable, and fast – with 100% customer focus.

Molded rubber and composite parts Manufactured in Bavaria

Comprehensive solutions from a single provider: We handle every step,

from developing the tooling concepts through to procurement and assembly of the finished module.

Elastomer Production

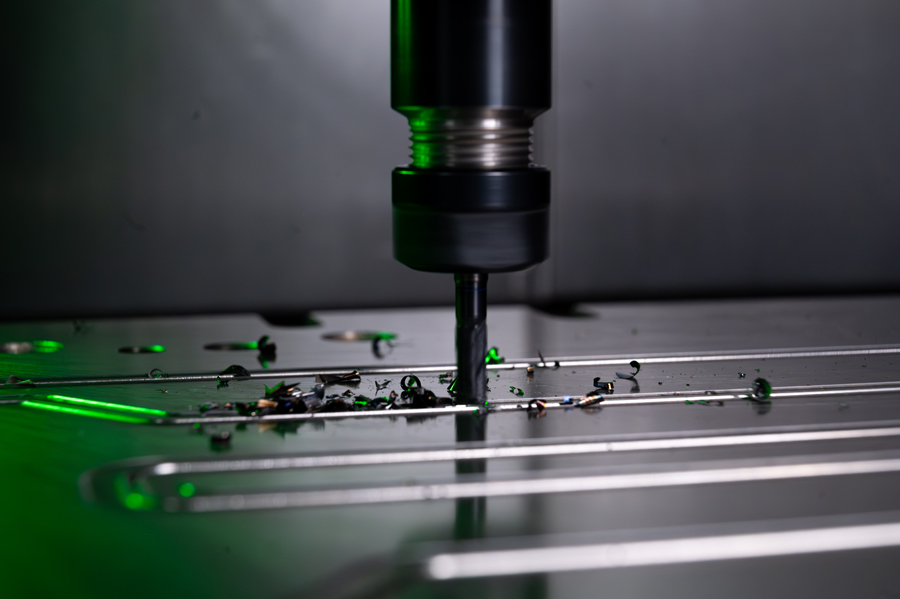

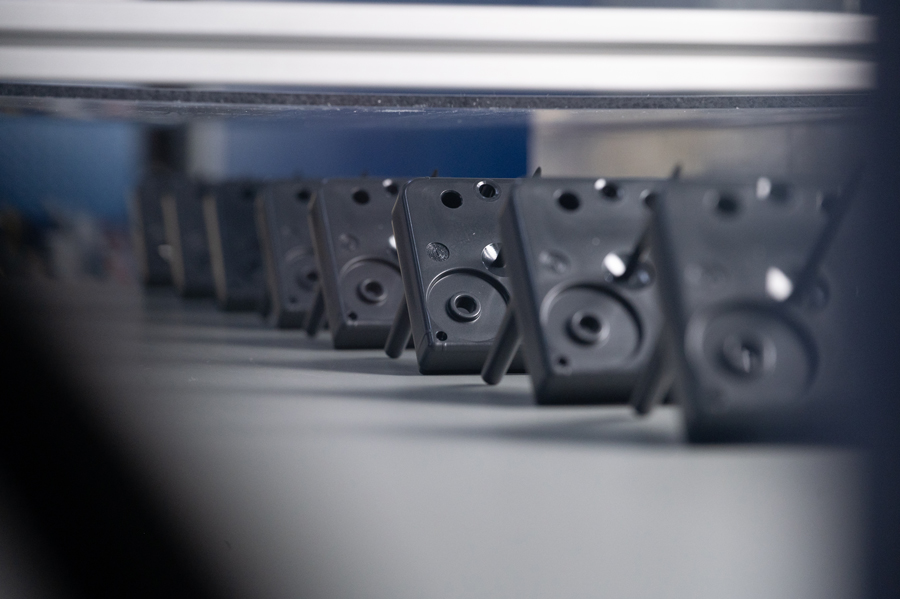

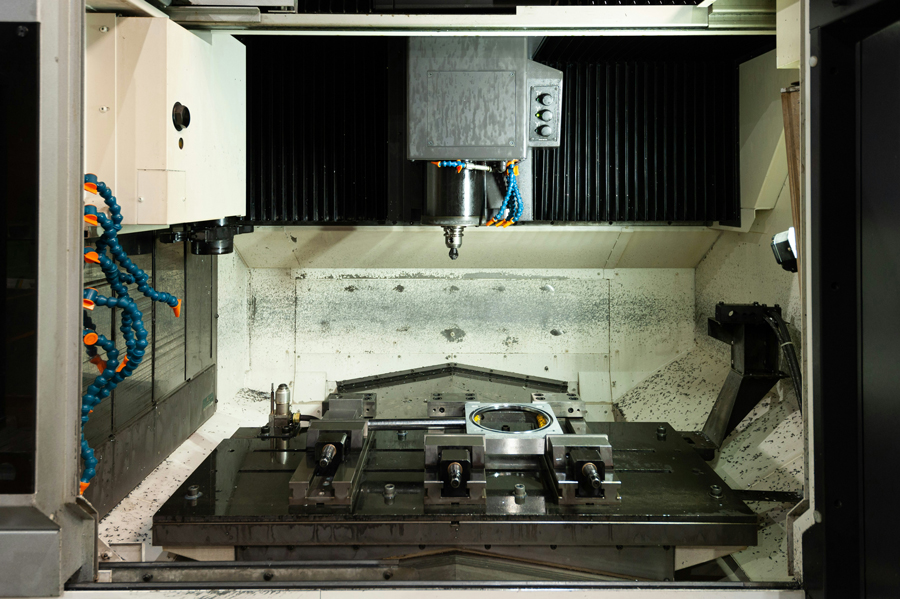

Tooling and Moldmaking

Express Service

Assembly Services

Supply Chain Management

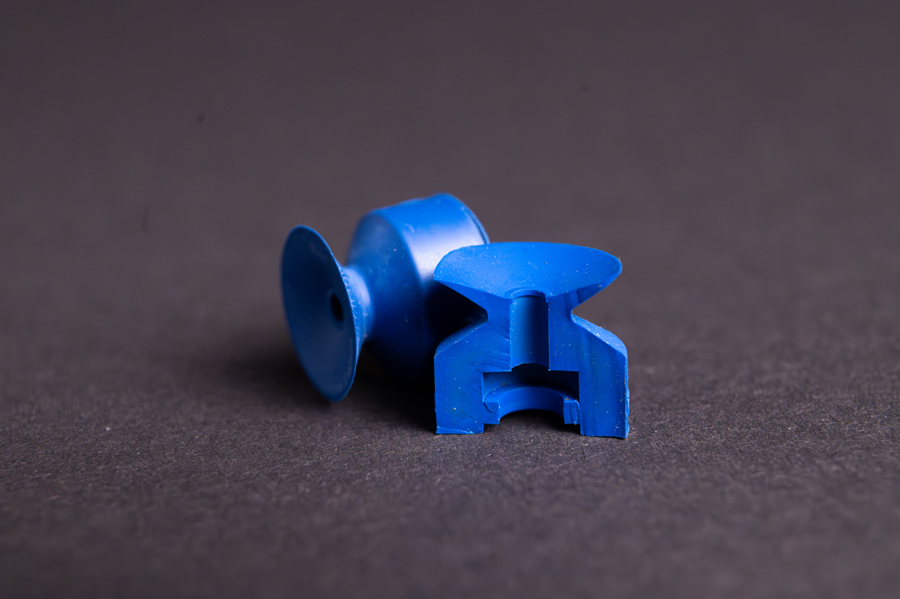

GUME unites rubber and metal – a hard-and-soft solution.

Technical Excellence:

With expertise in materials, manufacturing, and technology, we produce components that meet the highest standards.

Absolute Reliability:

We honor our commitments. Our goal is to deliver on time with zero defects.

Maximum Speed:

With our in-house toolmaking facilities and internal metal and plastic composite production, we can deliver your products quickly.

Total Customer Focus:

Every customer receives a response within 24 hours and is consistently supported by our five-star customer service.

The right Selection for your purpose

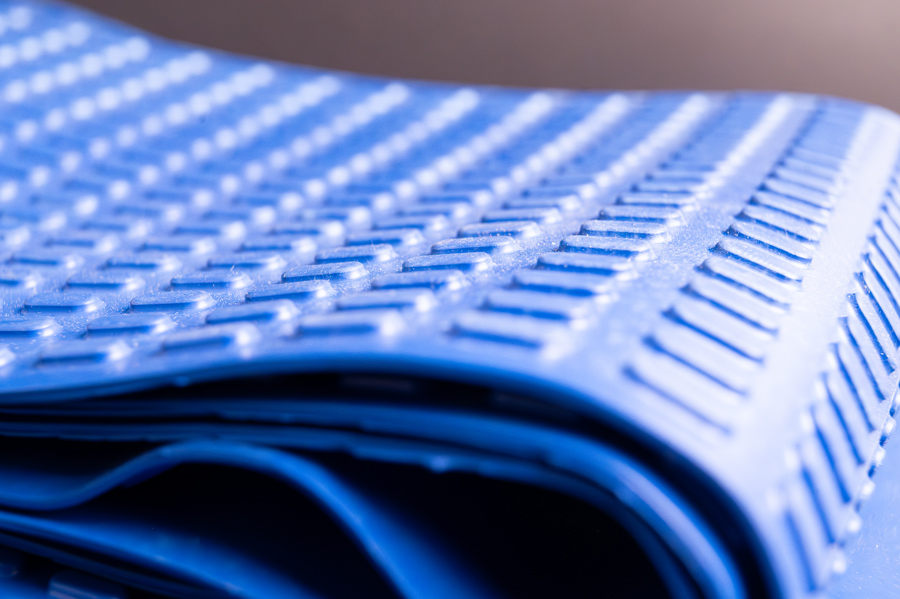

Fabric Composite Parts

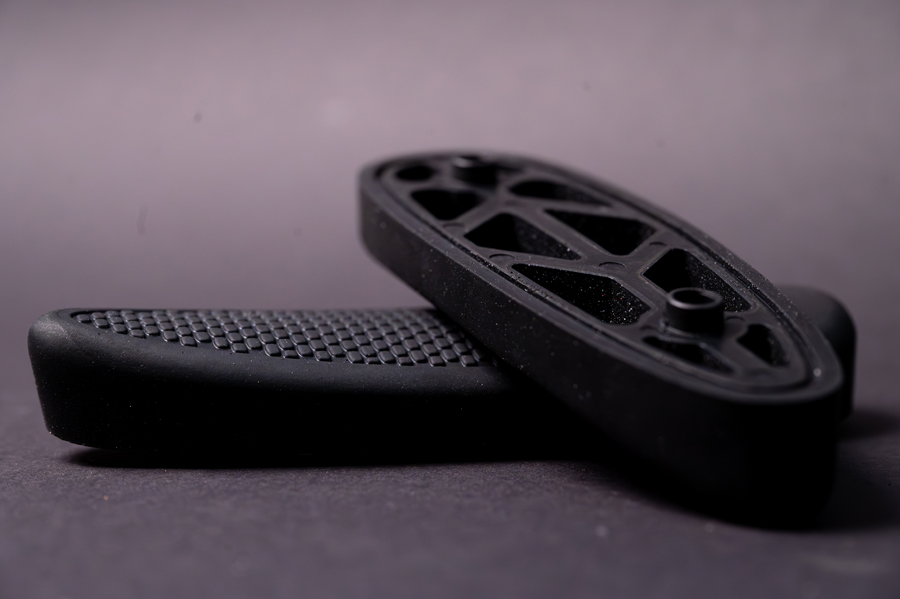

Plastic Composite Parts

Metal Composite Parts

TPE Molded Parts

Molded Silicone Parts

Elastomer components

Smart Manufacturing: We combine manufacturing expertise with a resilient supply chain

- 100% delivery performance with a resilient supply chain

- End-to-end responsibility from toolmaking and initial sampling to stable series production

- GUME as your proactive, reliable, and transparent partner

Technical rubber solutions for demanding industries

Medical Technology

Components for medical technology require precise production processes and often have to be biocompatible and sterilizable. We manufacture molded rubber parts and composite solutions from certified materials, supplying both single parts and series products, along with complete documentation.

Mechanical Engineering

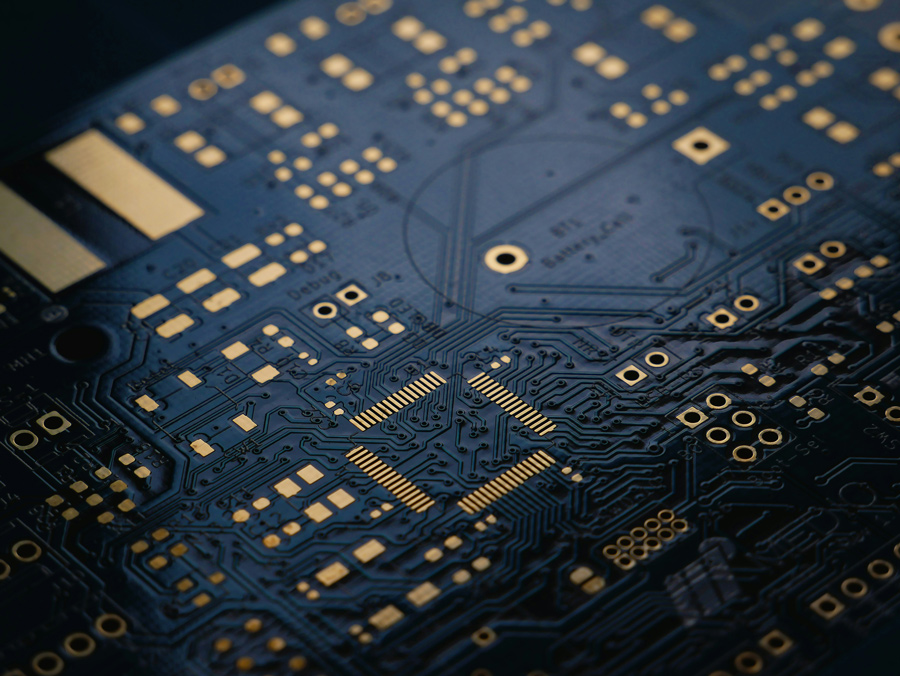

Electronic Devices

Infrastructure (Construction)

Defense Applications

The defense industry requires components with maximum robustness, functional safety, and resistance to extreme temperatures, loads, and media. We deliver precise, fail-safe, and robust solutions with strict adherence to safety-critical requirements.

Luft- und Raumfahrt

Aerospace demands lightweight, extremely durable, and certified molded parts. Components have to withstand temperature fluctuations, pressure, and vibration without compromising performance. Our high-performance elastomers and validated manufacturing processes ensure reliability, traceability, and absolute dependability for mission-critical applications.

Aktuelle Insights in die Elastomerfertigung

Bleiben Sie auf dem Laufenden über die neuesten Trends, Technologien und Erkenntnisse aus der Welt der Elastomerverarbeitung und Präzisionsfertigung. Unser Blog behandelt alles von Produktinnovationen bis hin zu Nachhaltigkeit.

Accelerated production: We combine in-house toolmaking with over 35 years of manufacturing experience

- Express service: Receive your first prototypes in 2 weeks, and start series production within 4 weeks

- 100% on time and delivered with zero defects

- Get a response within 24 hours