Express Service for Rubber Composite Parts

With our Express Service, we deliver molded rubber and composite parts in record time. Prototypes are typically available on request after 2 weeks, with series production starting after 4 weeks.

Accelerated transformation from concept to prototype

Speed

From toolmaking and initial sampling to the start of series production in just 4 weeks.

In-house toolmaking expertise

In-house toolmaking for maximum speed and flexibility.

Optimized processes

Processes are optimized for speed, and the team communicates smoothly and quickly.

Always on schedule – even when it’s urgent

Reliable, on-time performance for spare parts, rush orders, development projects, and short-notice ramp-ups.

01

Project discussion & order approval (Week 1)

You provide component CAD data, a component description, intended use, and target material properties. We immediately provide feedback on feasibility and timing.

02

Toolmaking & material ordering (Weeks 1–2)

We manufacture a custom tool in-house and place a rush order for any required raw materials.

03

Initial sampling & series release (Week 3)

You receive the first article samples for inspection. Upon approval, we launch series production immediately.

04

Series production & delivery (Week 4)

We produce your rubber composite parts, and begin immediately shipping partial quantities directly to you.

Your Express project with GuMe.

Design, manufacturing, initial sampling, and modifications - our in-house toolmaking facilities cover every step for the reliable production of molded rubber and composite parts.

Smart Manufacturing: We combine production expertise with a resilient supply chain

- 100% delivery performance with a resilient supply chain

- End-to-end responsibility from toolmaking and initial sampling to stable series production

- GUME as your proactive, reliable, and transparent partner

Insights into Our Customer Projects

Our projects illustrate how molded rubber parts and composite solutions are used in a wide range of areas, including long-lasting infrastructure projects, mechanical engineering, and safety-critical applications in aerospace and electronics.

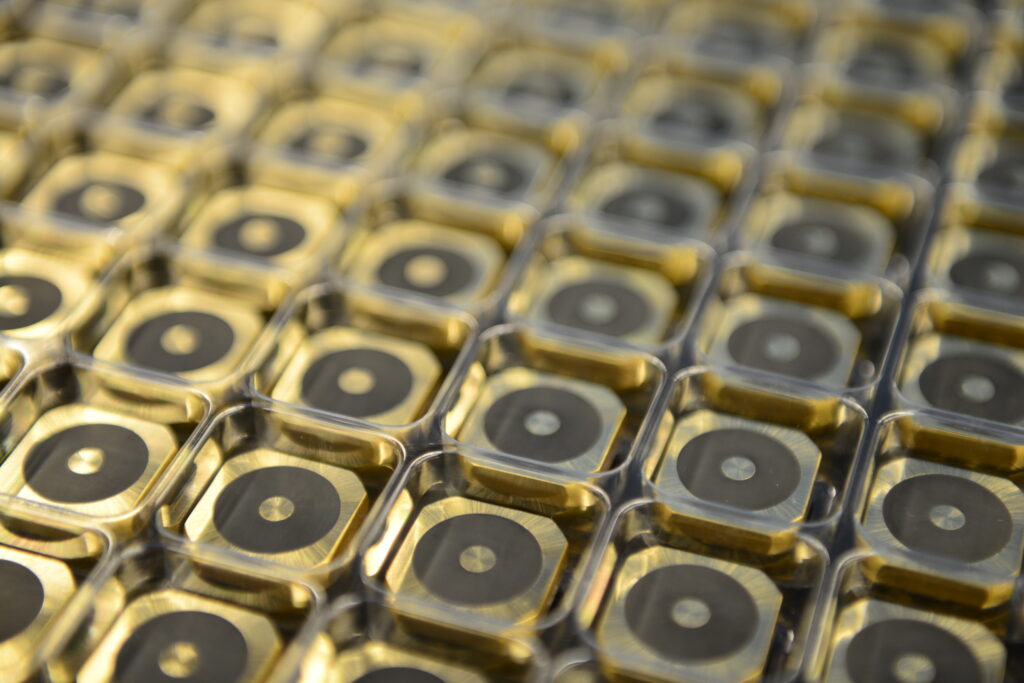

Electronics

Suction Cups for Cleanrooms

Suction cups, grippers, and molded rubber parts for automated inspection and test systems in cleanrooms and the semiconductor industry.

Learn more

Bauteile mit sehr breiter Temperaturbeständigkeit von –60 °C bis +200 °C unter dynamischer Beanspruchung, Wandstärken < 0,3 mm, gratfreie Ausführung sowie antistatische oder elektrisch leitfähige Werkstoffe.

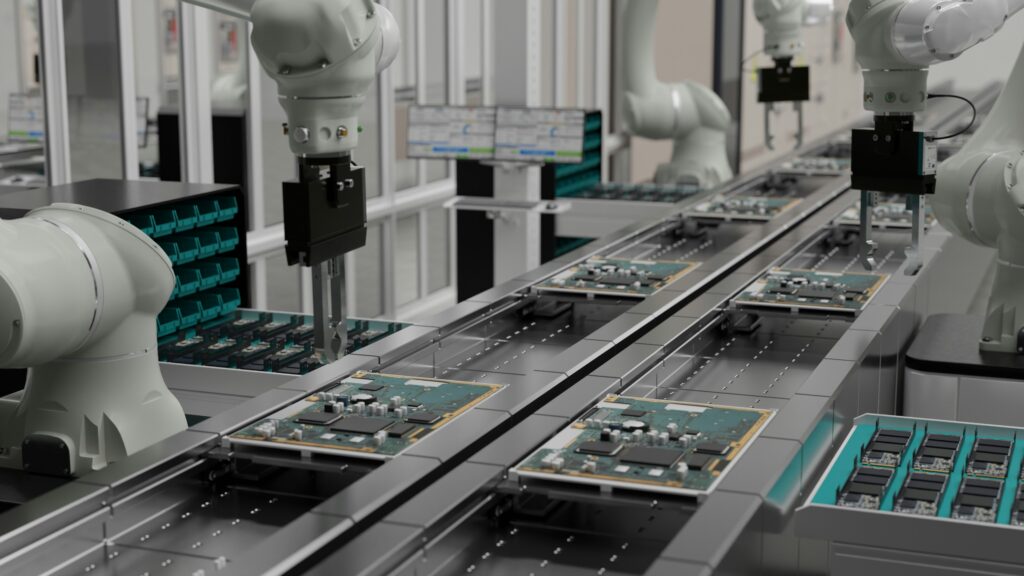

Mechanical Engineering

Miniature Silicone and Rubber Suction Cups

Suction cups, grippers, and molded rubber parts for PCB assembly equipment.

Learn more

Ultra-light components ranging from 0.01 g to 2 g, < 0.3 mm wall thicknesses, low to-zero burr, and complex geometries.

Defense Applications

Sealing Rings for Shipbuilding

Rubber metal and molded rubber parts for military applications, including sealing against seawater, vibration isolation of electrical devices, and rail elements for ammunition feed.

Learn more

Materials and components comply with military standards and meet the highest requirements for aging and weather resistance.

Do you have questions?

We have answers!

How quickly will I receive prototypes and series products via the Express Service?

Prototypes are typically available on request after 2 weeks, with series production starting after 4 weeks. Our in-house toolmaking and coordinated processes make this speed possible.

Which components can be manufactured in the Express Service?

We manufacture molded rubber parts, silicone and TPE components, as well as rubber composite parts with metal, plastic, or fabric. Special materials are ordered via a rush order, and we start production as soon as they are available.

Can the stated lead times always be guaranteed?

No. The figures are guideline values that depend primarily on the availability of raw material, as well as on component complexity and the speed of approvals.

What impact does raw material availability have on the Express Service?

Standard compounds are typically in stock or available at short notice; special formulations can extend timelines. In those cases, we either source from raw material suppliers that offer express delivery or conduct preliminary sampling with a faster-available material. At enquiry, we verify material availability, secure alternatives, and coordinate every step with you.

Does quality in the Express Service differ from series production?

No. The same standards apply for the Express Service. Precision, dimensional accuracy, and material quality are identical to regular series deliveries.

What quantities can be covered by the Express Service?

The Express Service is ideal for prototypes, pre-series, and small to medium series. For high-volume series, the same tools can be used immediately without requiring adjustments.

What prerequisites must be met for the Express Service?

A CAD model or a component drawing, plus close coordination, is sufficient. We develop the tooling concept and start implementation immediately.

What advantages does the Express Service offer for my projects?

You can significantly shorten development times, reduce project risks, and accelerate market access – without compromising on quality or reliability.

Accelerated production: We combine in-house toolmaking with over 35 years of manufacturing experience

- Express service: Receive your first prototypes in 2 weeks, and start series production within 4 weeks

- 100% on time and delivered with zero defects

- Get a response within 24 hours