Elastomer Production: ㅤ Custom Geometries, Reliably Manufactured

We produce elastomer parts based on your specifications. Our strength lies in manufacturing complex, custom-molded composite parts in close collaboration with your development team.

Special requirements call for custom rubber parts

Custom elastomer parts

Our production is geared toward individual elastomer solutions. Every component is developed and manufactured in accordance with your specific requirements.

Wide material portfolio

We process nearly all common elastomer compounds and precisely match material and properties to the intended use.

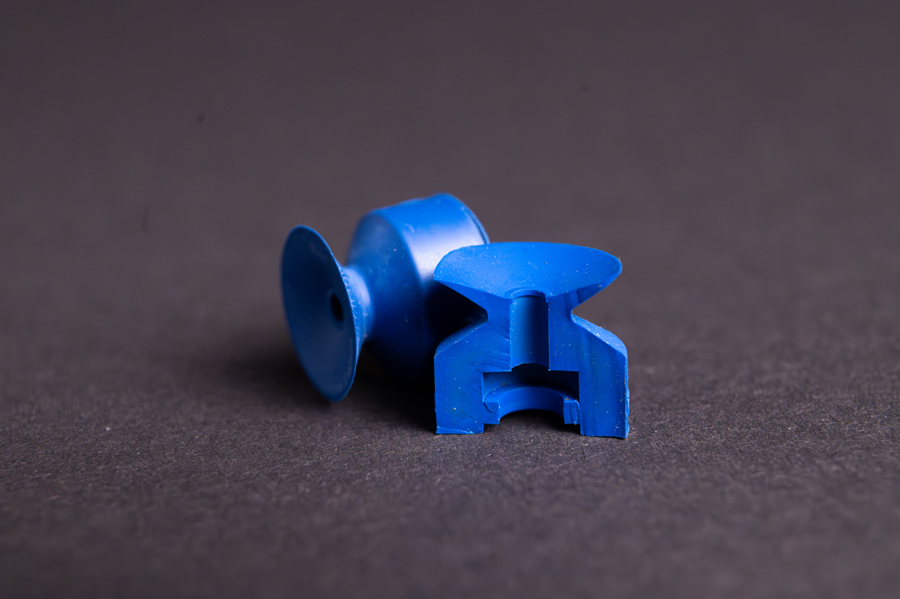

Manufacture of inserts

We produce metal and plastic inserts in-house and vulcanize them with a variety of elastomers.

Finishing and co-development

We also manufacture complex components that require close coordination and joint development with your team.

The right materials for your application

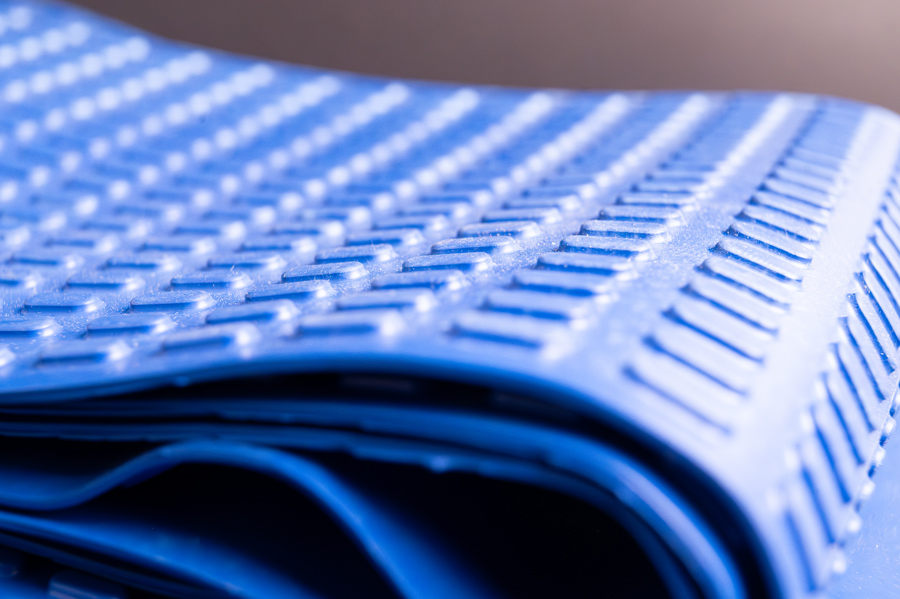

Fabric Composite Parts

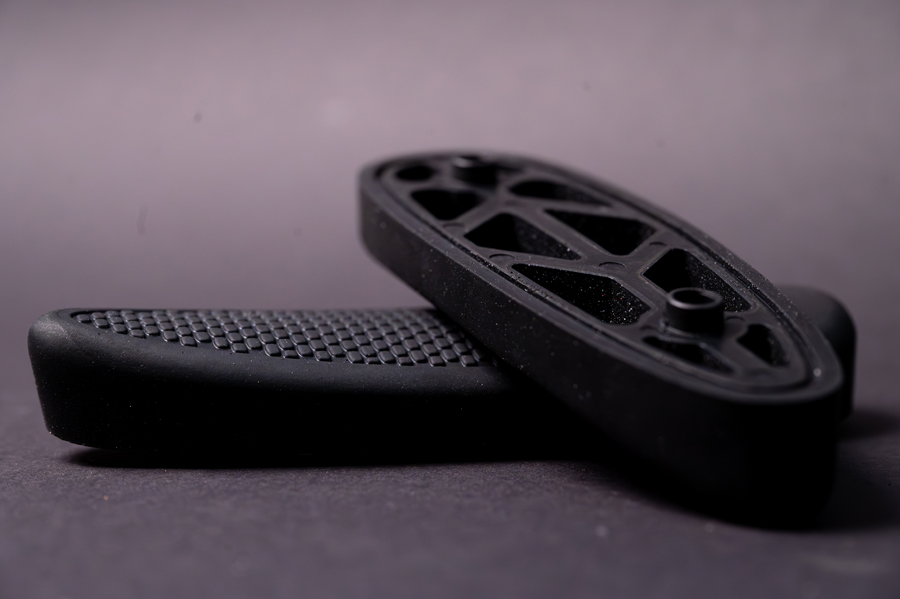

Plastic Composite Parts

Metal Composite Parts

TPE Molded Parts

Molded Silicone Parts

Elastomer components

Our Technologies

We cover the entire process chain from toolmaking to post-processing. This enables faster production, greater technical refinement, and high reliability.

CNC milling and EDM

Tool manufacturing for rubber production and metal inserts in all quantities.

Injection molding

Series production of rubber and plastic parts with high repeatability. This method is particularly efficient for medium and large batch sizes.

Learn more

Transfer molding

Ideal for medium to large series, intricate geometries, and the production of rubber-metal or other composite parts.

Learn more

Compression molding

Best suited for small to medium series. Ideal for components with lower quantities, higher wall thickness, and composite material requirements.

Learn more

Post processing

Comprehensive post-processing for flawless components, such as cryogenic deflashing, post-curing, etc.: burr free surfaces, enhanced material properties, and improved durability.

Insights into Our Customer Projects

Sealing Rings for Shipbuilding

Learn more

Rubber Metal Quick Clamping Device

Learn more

Safety Pins and Sealing Rings for Munitions

Learn more

Do you have questions?

We have answers!

What quantities can be produced?

We assemble small series, medium volumes, and larger quantities. Processes are scaled as needed while maintaining consistently high quality.

How quickly can you deliver?

Our standard lead times, depending on complexity and quantity, are about 8 weeks. For time-critical projects, we offer an Express Service starting at 4 weeks, enabling us to design and manufacture complex composite parts at short notice.

Can you also manufacture rubber metal or rubber plastic composite parts?

Yes. We specialize in rubber composite parts and manufacture rubber-metal, rubber-plastic, and rubber-fabric composite parts. We also produce metal and plastic inserts in our in-house facilities.

What is the maximum component size you can produce?

Do you advise clients regarding development processes?

Yes, we advise you on material selection and design for the manufacturing process. Together, we analyze your operating conditions and develop the optimal solution for your application.

Are your materials suitable for food or medical products?

Yes, we offer FDA-compliant and biocompatible materials that are pre-certified by the raw material manufacturer. This enables us to manufacture components for medical devices as well. We gladly provide you with all relevant material, certificates, and declarations of conformity.

Reliable Production: We combine individual solutions with reliable partnerships.

- 100% custom-engineered component geometries

- Reliable, on-time delivery

- GUME as your proactive, reliable, and transparent partner